how to use a water jet cutter

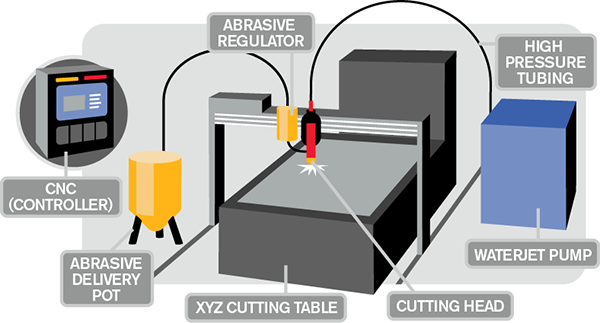

In the waterjet cutting process an ultra-high pressure pump pressurizes the water to over 60000psi and then shoots the water out through. A waterjet cutter also known as a waterjet cutting machine is a cutting machine that harnesses the power of pressurized water typically mixed with an abrasive material dispersed.

Water Jet Cutting Norwood Medical

The waterjet cutter can be used either.

. In some cases the water is supplemented with. The process is used to produce name plates signage and company logos. Working principle ofWaterjet cutting machine.

In this process pressurizing pumps deliver high-pressure jets of water. Aluminum waterjet cutting involves a cutting head that emits a high-pressure jet of water focused on the material that requires cutting. Water jet cutting is a kind of sheet metal fabrication process cutting nearly any type of material soft and hard.

A water jet cutter is a device capable of cutting right into metal or other materials utilizing a jet of water at high speed rate and pressure. The process is used to produce name plates signage and. Tips for Your DIY Water Jet Cutter.

The smaller orifice the smaller the cut width kerf. A water jet cutter also known as a water jet or waterjet is an industrial tool capable of cutting a wide variety of materials using an extremely high-press. It does not generate heat making it suitable for heat-sensitive materials.

Using a ruby or diamond jewel the orifice focuses the high-pressure water. A water jet cutter also known as a water jet or waterjet is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water or a mixture of water. Industrial water jet cutting though is a non-thermal process.

The high pressure of the water jet cuts. A waterjet cutter can deliver up to 30 kW of power within a fine high pressure waterjet at the size of a needle and can cut almost any material. Here is Teenking CNC Machinery which produces Waterjet Cutting Machine Water Jet Cutting Machine Stone Cutting Machine.

Stone can be cut using a water jet cutter to make a variety of carvings. Water jet cutting is used to create permanent name plates out of heavy metals. Water cutters operate by pushing water out of a cutting head at extremely high speeds.

The smaller orifice the smaller the cut width kerf. Tips for Your DIY Water Jet Cutter. The diameter of the orifice helps determine the cut width kerf.

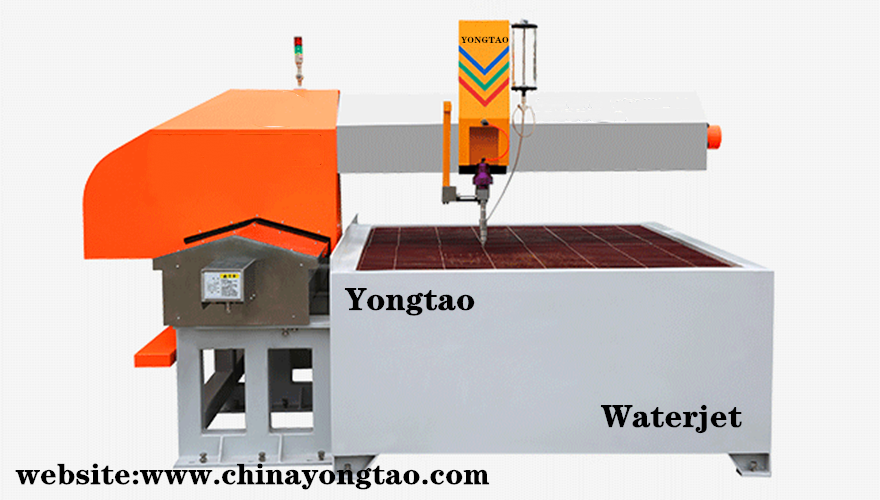

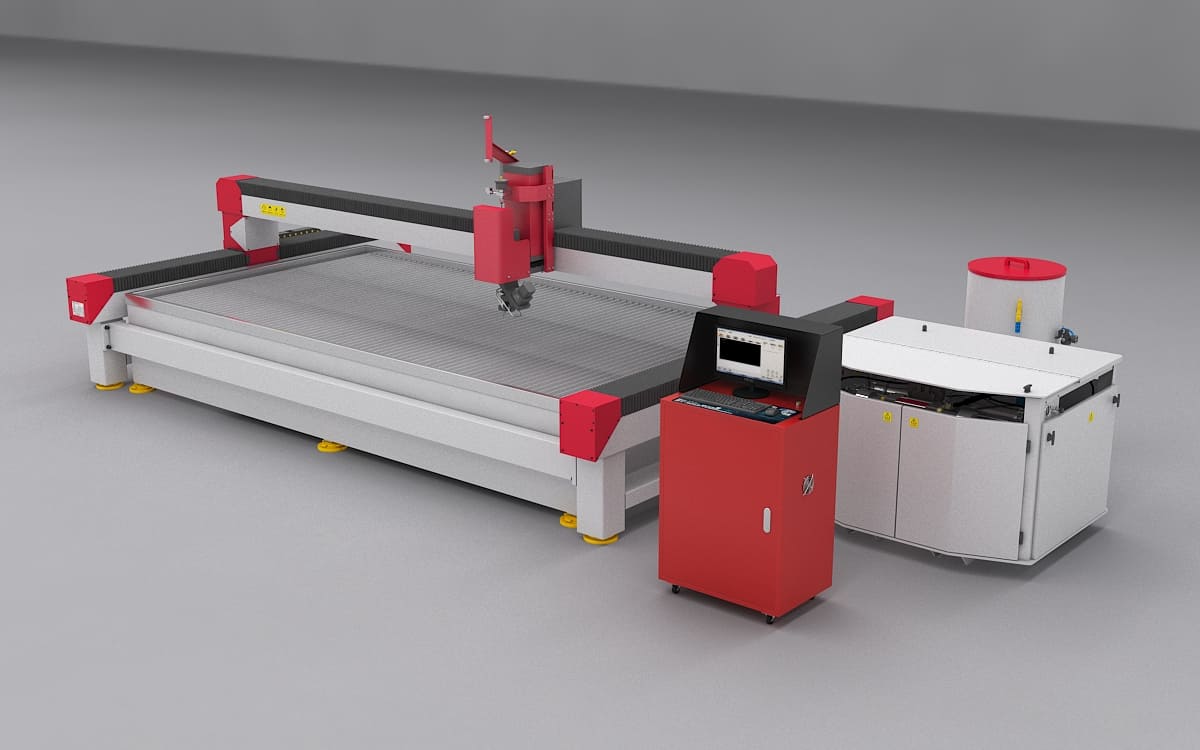

Cnc Water Jet Cutting Machine For Sale Small Waterjet Cutting Machine

The Design And Development Of The First Ever Low Cost Waterjet Cutter Youtube

Best Of Waterjet Cutting Youtube

Base Employs Robotic Water Jet Cutter To Cut Sheet Metal Robins Air Force Base Article Display

Water Jet Cutting Aimes Srinivas Integrated Campus Mukka

Waterjet Cutting Service Precision Parts Specialists Klinger Igi

Abrasive Water Jet Cutting Uhde Hpt

Laser Cutter Vs Waterjet Cutting 5 Points To Set Them Apart

Water Cutting Machine What Are The Dangers Of Waterjet Cutting

6 X 3 Water Jet Cutter 55k Psi 3 Axis Excellent For Glass Why Buy Used

Water Jet Cutting What Is It How Does It Work Types Uses

Sustainability And Waterjet Cutter Woodguide Org

Glass Cutting Waterjet Cutting Swift Glass

Water Jet Cutting Machine In China Omni Cnc

An Engineer S Guide To Waterjet Cutting Engineering Com

Accurl 3d Waterjet Cutting Machine With 5 Axis Water Jet Cnc Cutting Price For Sale Youtube

Abrasive Water Jet Machining How Water Jet Cutter Works

Using Water Jets To Cut Unique Parts And Tools

What Are The Benefits Of Using Waterjet Technology For Precision Cutting